GEA AUTOMATED MILKING SOLUTIONS

ABOUT GEA

Dairy farming, and the labor ecosystem around it is changing rapidly. Today, farmers utilize milking robots, automation, digitalization and smart solutions to create profitable and sustainable milk production. GEA offers a wide range of solutions to farmers around the world to maximize their productivity and the quality of their milk.

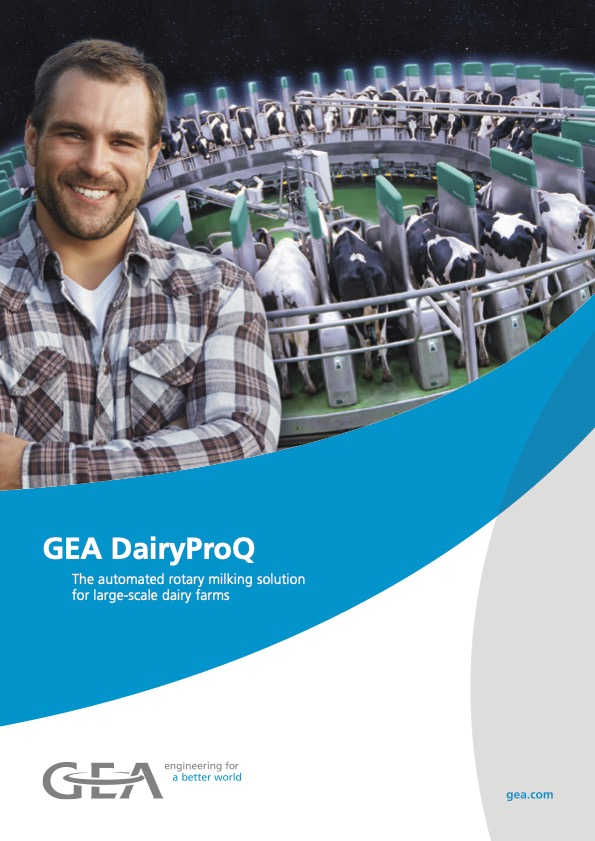

GEA DairyProQ

GEA’s DairyProQ rotary parlor opens groundbreaking production possibilities for milking herds of 500 cows and up. With 28-80 milking stations, approximately 120-400 cows can be automatically milked per hour, with just one operator supervising the entire process. Cows appreciate the individual attention they receive during the milking process, and the spacious, comfortable

surroundings provide a sense of serene calm. The unique milking routine, from attachment to dipping and cleaning, takes place in a fully automated process with consistent precision. The DairyProQ’s high-performance technology guarantees round-the-clock productivity with the highest level of reliability.

Each milking stall module operates independently and has its own decentralized attachment activator, so milking processes are available at all times. The parlor’s high-tech components and modular design produce consistently high quality. The DairyProQ also comes with an innovative service plan from Dairy Specialists that allows repairs and maintenance to happen during operation, reducing downtime.

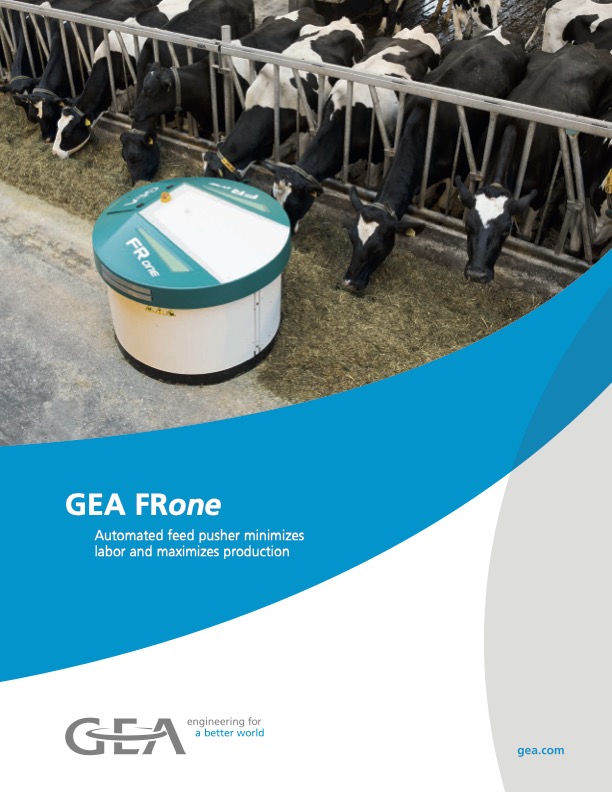

GEA FRone

Intelligent technology is attractive, especially when it makes your work easier and saves valuable time. The fully automated feed pusher, FRone, by GEA moves feed towards the feed fence at the times you define and according to the routes you set. This ensures that your cows have access to fresh, high-quality feed around the clock – even lower-ranking animals in the second feeding group.

Precise processes ensure optimum feed utilization:

The GEA FRone combines tried and tested technology with maximum precision and reliability. Regularly pushing the feed forward ensures your animals can get the most out of the nutrition you provide – a welcome cost saving for your business.

Simple programming:

The handy remote control enables you to program a 24 hour cycle of routes and start times to suit you and your animals, quickly and easily. And you can configure as many different routes as you like. There is also an additional option to clean the feed alley passageway.

Fast charging:

The GEA FRone can even charge itself: every time it completes a route, it returns to the charging station in the barn to recharge until the next programmed feed push.

Your advantages:

- Saves more than 90 working hours per year (based on manual feed pushing for 5 minutes, 3 times per day)

- Higher milk yields (between 1 % – 3 %)

- Improved animal health

- More frequent use of the milking robot

- Payback time of 1 – 4 years

- Speed of 6 meters per minute

- Can operate for up to 19 hours per day (5 hours total charging time)

- For herds up to 2,000 cows

- Unlimited routes

Custom design and solutions

main office

Dairy Specialists, LLC

3309 Empire Street

Evans, CO 80620

MAIN

970-330-1870

24-HOUR SERVICE

970-330-1870

FAX

970-330-1872

Ulysses, KS Location

1407 E Oklahoma Ave

Ulysses, KS 67880

MAIN

620-384-6262

Tillamook, OR Location

2 Stillwell Ave

Tillamook, OR 97141

Independence, OR Location

605 S 3rd St

Independence, OR 97351

MAIN / FAX

503-354-5359

24-HOUR SERVICE

503-812-4452

CONNECT

Hours: 8:00AM – 5:00PM

Email: info@dairyspecialists.com

main office

Dairy Specialists, LLC

3309 Empire Street

Evans, CO 80620

MAIN

970-330-1870

24-HOUR SERVICE

970-330-1870

FAX

970-330-1872

-

Ulysses, KS Location

1407 E Oklahoma Ave

Ulysses, KS 67880

MAIN

620-384-6262

-

Tillamook, OR Location

2 Stillwell Ave

Tillamook, OR 97141

Independence, OR Location

605 S 3rd St

Independence, OR 97351

MAIN / FAX

503-354-5359

24-HOUR SERVICE

503-812-4452

CONNECT

Hours: 8:00AM – 5:00PM

Email: info@dairyspecialists.com